How To Repair Nylon Material

Nylon has an indelible popularity within the 3D printing industry. It is applicable to both material extrusion and pulverization bed fusion 3D printing technologies. It tin be difficult to print on a desktop 3d printer, so we've gathered a few tips and tricks.

About Nylon

Nylon is a synthetic polymer which is based on polyamides. Information technology's resilient, strong, durable and a tad bit flexible. Another property is that information technology's hydroscopic. This means it absorbs liquids. This makes nylon a good choice when yous need to dye your printed part in a certain color. It also means that nylon filament has a short shelf live and is difficult to store.

Functional 3D printed parts

Since nylon has such a unique durability to flexibility ratio, it is oftentimes used for functional parts. Remember of prosthetics, medical equipment, connectors and living hinges.

Why Nylon?

Nylon has its ain distinct pros and cons:

Pros

- Nylon is very resilient and durable.

- Fantabulous force to flexibility ratio.

- Easily colored / dyed.

- UV resistant and college chemical resistance than PLA or ABS.

Cons

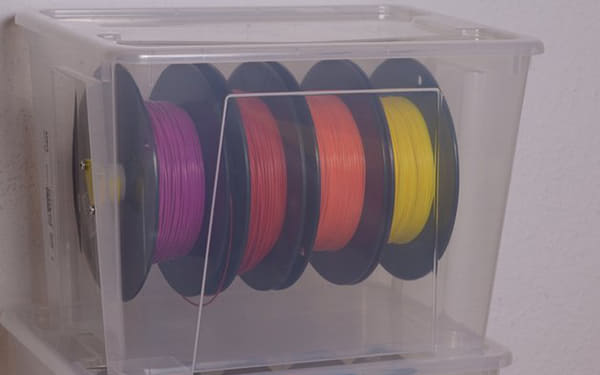

- Nylon is very sensitive to moisture and must be kept dry.

- You'll need to store nylon filament in a wet free container or drybox.

- You lot might need to dry information technology in an oven prior to printing.

- First layers tends to warp.

- Most nylon brands have a shelf life of max. 12 months.

- Nylon can (potentially) compress during cooling so printed parts may be less precise.

Requirements

There are quite a few desktop printers that are capable of printing nylon filament. Due to it's wet absorption and being sensitive to temperature changes we recommend to use:

- A print chamber enclosure (temperature controlled would be even meliorate).

- Heated bed non necessary for all nylon filaments (still preferable).

- Some sort of adhesion spray or glue stick to forestall warping.

Print Temperature

Things can get tricky here. Nylons can vary widely in terms of temperatures, cause each brand has their own range of nylons. Temperatures tin can range from 446 °F / 230 °C all the style up to 572 °F / 300 °C.

Source: https://3dprinting.com/filament/3d-print-nylon-filament-tips/

Posted by: saddlerbecrut.blogspot.com

0 Response to "How To Repair Nylon Material"

Post a Comment